Industrial balers can be sourced online through supplier websites who buy and sell used industrial equipment, or through baler companies or refurbishment companies. Read More…

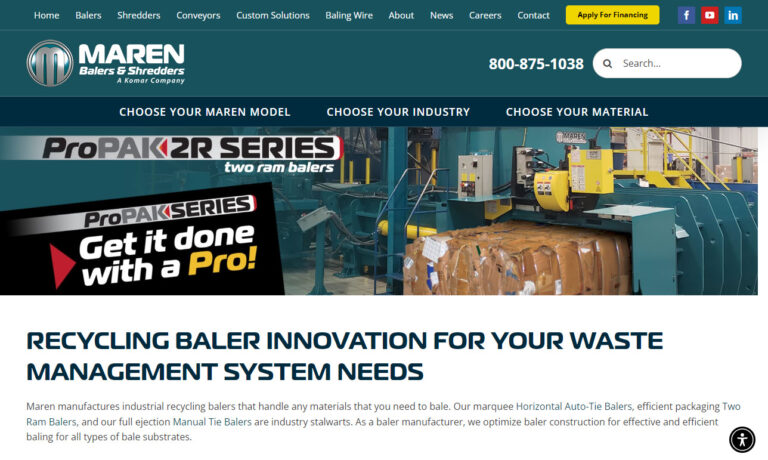

Since 1962, Maren has led the industry, building powerful and reliable manual tie, automatic tie and two ram balers, shredders and conveyors. That’s why many of the most successful paper & box plants, distribution centers, post consumer recyclers, and printers rely on Maren Balers to bolster their bottom line. Maren’s reputation for great customer service has carried from generation to...

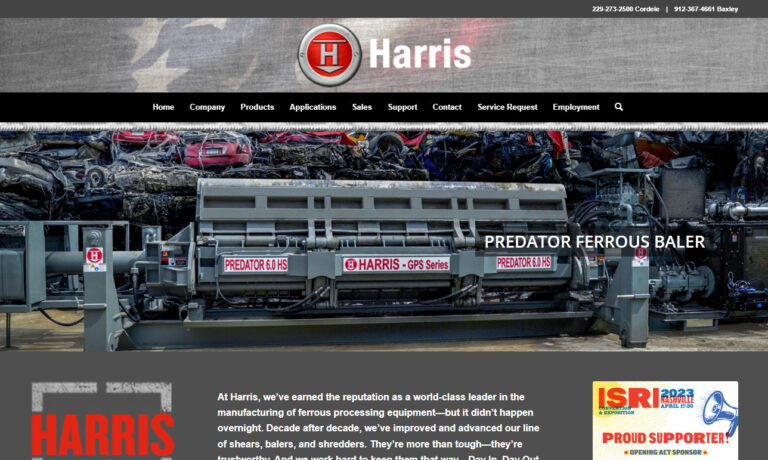

In Business for over 100 years, Harris has maintained its position as the industry leader by paying attention to its customers needs. Our vertical, horizontal and 2-ram balers process recovered papers, paperboard, plastics, solid waste and light ferrous and non ferrous metals. Harris supplies the right equipment for your application.

The only thing stronger than an Excel baler is the loyalty of our customers. Excel continues to break new ground by designing equipment with energy-saving technologies, developing balers to fit your business and solve your problems, and introducing products that process more material and make you more money. While the competition makes their balers cheaper, we make Excel balers better!

SSI Shredding Systems provides a wide range of waste management products, including industrial shredders, industrial balers, industrial reducers and industrial compactors.

Founded in 1981, Ely Enterprises, Inc. has established itself as a leader in the baler manufacturing industry, specializing in premium baler products essential for effective material handling and waste management. Our balers are designed to maximize efficiency, reduce waste, and help companies optimize their recycling processes, benefiting industries from recycling and manufacturing to waste...

If you are currently paying for the disposal of cardboard, paper, plastic or non-ferrous metals; than consider International Baler Corporation & our range of balers and related equipment.

More Used Baler Manufacturers

Balers are durable and reliable machines and if refurbished correctly and in good working condition, a used industrial baler can work for many more years. It is important to thoroughly test used equipment before purchasing to ensure that it works correctly. Balers, or compactors, are used to compress, compact and bind many different types of materials in high or low volumes according to design and need and there are many factors to consider when choosing a baler. It is important to consider what type of material needs to be baled and in what volumes.

Most balers are electrically powered and can come with a hydraulic system which helps to minimize heat production and energy loss, and to provide the pressure required to crush material. There are two main styles of baler according to direction of material flow - horizontal and vertical. Horizontal balers are used with heavier, denser materials, and while they take up more floor space, are able to run on a continuous process with a greater load capacity.

Vertical balers are used for lighter, less dense materials that are fed into the baler from the top. Vertical balers require manual unloading which means the overall output is lower, but vertical balers do produce less waste than horizontal balers which further supports a primary purpose of bailing.

Sourcing and purchasing a used baler would save a manufacturer initially in terms of cost, but would also continue to make industrial processes more budget friendly. For high waste-producing industries including automotive manufacturing, plastics manufacturing and grocery stores or food services, the necessity for compacting and baling is both environmental and economical.

Proper disposal and recycling of materials can be a costly endeavor for a company. Baling, or industrial compacting, is one way in which to reduce the bulk volume of material and thus reduce the costs required to transport it or dispose of it. Furthermore, a reduction in waste volume cuts down the carbon emissions required in the process of recycling.

In some cases, complete systems can be designed around an industrial baler for recycling and composting purposes, allowing businesses to be more environmentally responsible. Baling equipment, used and new, continues to play a large role in assisting industries in reducing their carbon footprint.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

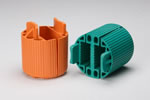

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services