Generally, two overarching models of the baling press exist: the vertical press and the horizontal press. As one would expect, vertical baling presses feature a hydraulic arm that operates on a vertical plane and horizontal baling presses has an arm that works on a horizontal plane. Read More…

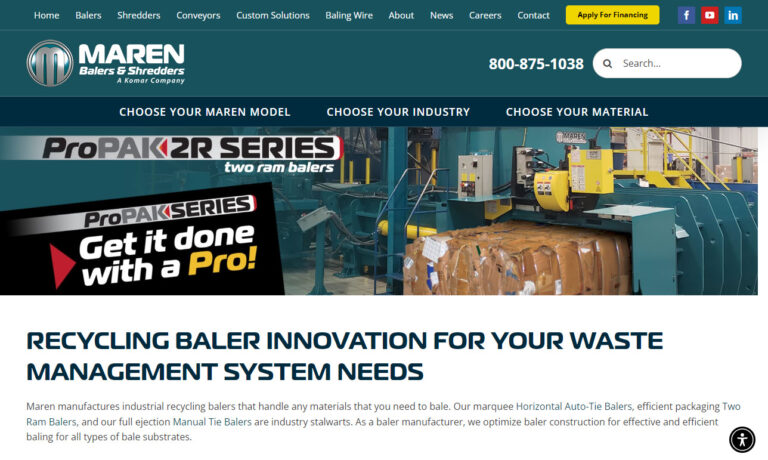

Since 1962, Maren has led the industry, building powerful and reliable manual tie, automatic tie and two ram balers, shredders and conveyors. That’s why many of the most successful paper & box plants, distribution centers, post consumer recyclers, and printers rely on Maren Balers to bolster their bottom line. Maren’s reputation for great customer service has carried from generation to...

The only thing stronger than an Excel baler is the loyalty of our customers. Excel continues to break new ground by designing equipment with energy-saving technologies, developing balers to fit your business and solve your problems, and introducing products that process more material and make you more money. While the competition makes their balers cheaper, we make Excel balers better!

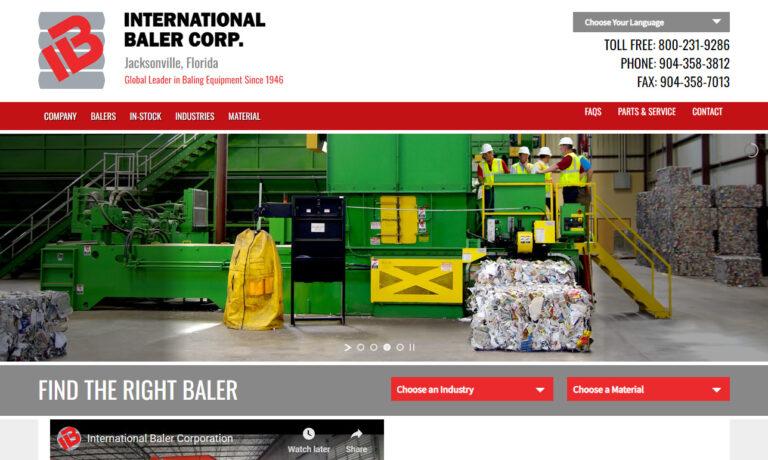

If you are currently paying for the disposal of cardboard, paper, plastic or non-ferrous metals; than consider International Baler Corporation & our range of balers and related equipment.

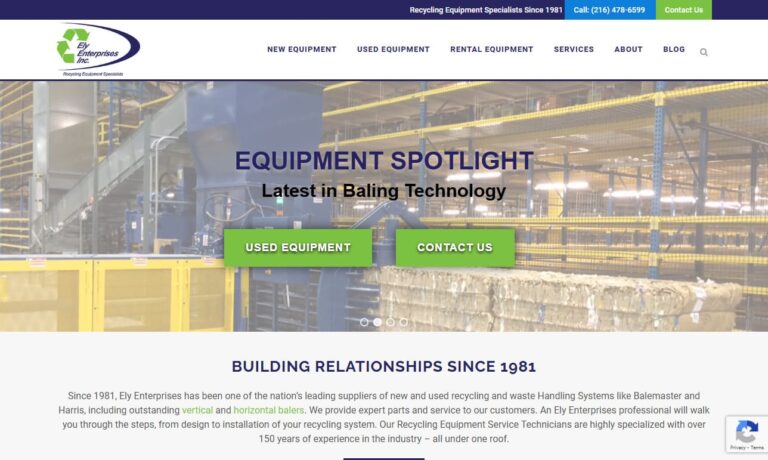

Founded in 1981, Ely Enterprises, Inc. has established itself as a leader in the baler manufacturing industry, specializing in premium baler products essential for effective material handling and waste management. Our balers are designed to maximize efficiency, reduce waste, and help companies optimize their recycling processes, benefiting industries from recycling and manufacturing to waste...

SSI Shredding Systems provides a wide range of waste management products, including industrial shredders, industrial balers, industrial reducers and industrial compactors.

More Baling Press Manufacturers

To work, materials are loaded onto the baling press into a hopper or container, and when said container is full, the arm can be actuated to begin compressing the materials. Baling presses may be simple and labor-intensive or complex and automated. Baling presses may compress various types of materials, such as hay, shredded paper, recycling paper, recycling plastic, aluminum and waste. Some baling presses, however, are made to be used only with one specific material. Examples of such baling presses are the tire baler and a baling press designed to compact stretch wrap.

Baling presses are used in several industries, such as in agriculture, where they are used create hay bales on farms. Another common industry in which baling presses are used is the recycling industry. Here, materials such as plastic, rubber and metal can be baled for transport, storage or the next stage of the recycling process. Likewise, waste services create bales for similar purposes. The maximum size of a bale generally corresponds to the size of the baling press, and many manufacturers will specify a press' safe maximum load size.

Exceeding the specified limit increases the chances of causing damage to the baling press. If your main objective is speed of production, then a smaller baling press may be the choice for you. Large baling presses create larger bales, but smaller baling presses work more quickly, allowing a user to create more bales within a set timeframe. For ease of use, efficiency of use and general convenience, baling presses may be portable. Whatever your compression needs, baling presses are a great, efficient way to move things along.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services