Baler machines use a hydraulic ram to compress various materials into compact shapes for easy transport, processing, storage, or recycling. A baler can be adapted depending on the waste material it processes. Read More…

Since 1962, Maren has led the industry, building powerful and reliable manual tie, automatic tie and two ram balers, shredders and conveyors. That’s why many of the most successful paper & box plants, distribution centers, post consumer recyclers, and printers rely on Maren Balers to bolster their bottom line. Maren’s reputation for great customer service has carried from generation to...

The only thing stronger than an Excel baler is the loyalty of our customers. Excel continues to break new ground by designing equipment with energy-saving technologies, developing balers to fit your business and solve your problems, and introducing products that process more material and make you more money. While the competition makes their balers cheaper, we make Excel balers better!

If you are currently paying for the disposal of cardboard, paper, plastic or non-ferrous metals; than consider International Baler Corporation & our range of balers and related equipment.

Founded in 1981, Ely Enterprises, Inc. has established itself as a leader in the baler manufacturing industry, specializing in premium baler products essential for effective material handling and waste management. Our balers are designed to maximize efficiency, reduce waste, and help companies optimize their recycling processes, benefiting industries from recycling and manufacturing to waste...

SSI Shredding Systems provides a wide range of waste management products, including industrial shredders, industrial balers, industrial reducers and industrial compactors.

More Baling Machine Manufacturers

How Baler Machines Work: An In-Depth Guide to Baling Equipment Operation

Baler machines are essential equipment in modern recycling, waste management, and material processing industries. Understanding how these industrial balers operate can help businesses and facility managers optimize their recycling processes, reduce costs, and improve workplace safety.

To begin the baling process, soft or hard waste—such as cardboard, plastics, paper, metal, textiles, or agricultural byproducts—is loaded into the baler machine. The material is typically fed through a hopper and tin pan connected to a hydraulic ram system.

The hydraulic ram, enclosed within a durable steel frame, is powered by an electric motor-driven hydraulic pump. This electric pump pressurizes hydraulic fluid within the cylinder, generating the immense compression force needed to compact the material. The ram then compresses the waste into a dense, uniform block—commonly referred to as a "bale."

The bale chamber determines the final shape and dimensions of the bale before it’s ejected from the machine. During or prior to ejection, the compacted bales are secured with galvanized or black annealed baling wire or heavy-duty plastic strapping to maintain their integrity during handling, transport, and storage. The ejection ram then pushes the finished bale out of the chamber, also clearing out any residual or uncompressed material for the next batch.

Modern balers are engineered for durability, with robust steel frames and thoughtfully designed structures that ensure longevity and minimal maintenance. Key durability features include anti-wear steel plates for reinforcement, precisely fitted main rams to reduce mechanical wear, and integrated shearing tools to evenly distribute operational stress. High-performance balers utilize precision-manufactured components to eliminate misalignment, minimize breakdowns, and prevent premature equipment wear.

Curious about how baler machines can be integrated into your workflow? Scroll down to explore key industry applications and case studies.

Types Of Balers: Comparing Industrial Baler Machine Varieties

Choosing the right type of baler machine depends on your materials, processing volume, facility space, and operational needs. Below, we outline the most common baler types available in the market, their distinguishing features, and ideal use cases.

Vertical Balers

Vertical balers are compact, versatile machines ideal for small to medium-scale recycling applications. These balers utilize a vertical, downward-acting hydraulic ram to compress waste materials such as cardboard, plastic film, textiles, and light metals.

Loaded from the top, vertical balers require manual feeding but produce standardized bales that are easy to handle and transport. Although they may deliver inconsistent bale densities compared to larger models, vertical balers are cost-effective, energy-efficient, and suitable for retail stores, small warehouses, and businesses that generate moderate volumes of recyclable waste. Their smaller footprint allows for installation in tight spaces, making them a popular choice for urban facilities and organizations seeking to improve sustainability on a budget.

Want to know which vertical baler suits your needs? Browse our vertical baler selection and request custom quotes from leading manufacturers.

Horizontal Balers

Horizontal balers are engineered for high-capacity operations, such as distribution centers, recycling plants, and manufacturing facilities. These machines apply compression force horizontally, allowing for continuous feeding and automated operation.

Horizontal balers are capable of processing large volumes of material—such as paper, cardboard, plastics, aluminum cans, and certain scrap metals—yielding consistently dense, mill-size bales that maximize payloads and minimize transportation costs. Many models are equipped with shear blades to cut oversized materials within the hopper, preventing jams and ensuring smooth, uninterrupted operation.

These balers require more floor space and a higher capital investment but deliver significant labor savings and operational efficiency for high-throughput environments. Automated tying systems, conveyor integrations, and remote monitoring options make horizontal balers a preferred solution for companies seeking to optimize their recycling and waste management processes at scale.

Need help selecting a horizontal baler for your business? Compare models and consult with our experts for tailored recommendations.

Single Ram Balers

Single ram balers utilize a single hydraulic ram to compress and eject material. Available in both closed door and open extrusion designs, these balers are suitable for processing a broad range of recyclables—such as paper, cardboard, plastics, and certain metals.

Closed-door single ram balers compress material against a robust steel door, which is opened post-compression to release the bale. Open extrusion single ram balers, by contrast, continuously eject bales through an open end, making them ideal for uninterrupted processing and higher throughput facilities.

Curious about the benefits of single ram balers? See how single ram balers can streamline your recycling operation.

Double Ram Balers

Double ram balers are heavy-duty machines equipped with two hydraulic rams, each serving distinct functions. The primary ram delivers compression force, while the secondary ram controls material rebound, making double ram balers particularly effective for baling challenging materials such as rubber, foam, or high-memory plastics.

These balers are larger, more expensive, and typically reserved for industrial or commercial settings where maximum throughput and material versatility are required. Common applications include metal recycling, fiber processing, and facilities dealing with high volumes of rigid or springy waste.

Circular or Tractor Balers (Round Balers)

Round balers, also known as circular or tractor balers, are mobile baling solutions commonly used in agriculture. These machines, typically attached to tractors, roll and compress materials—such as hay, straw, alfalfa, clover, or timothy grass—into large, cylindrical bales.

Round balers offer efficient gathering and packaging of loose crop residue, streamlining fieldwork and enhancing storage and transport logistics for livestock feed and bedding. Their mobility and adaptability make them indispensable for farms and ranches seeking to maximize productivity during harvest.

Other Types of Baler Machines

- Ferrous balers: Specifically designed for compacting and processing scrap metals—including iron, steel, and other ferrous materials—into dense, transportable bales for recycling or smelting operations.

- Liquid extraction balers: Engineered to drain liquids from processed materials (such as beverage containers or wet waste) while compressing the solids. These balers are constructed with corrosion-resistant materials and are crucial for food, beverage, and pharmaceutical waste management.

- Logger balers: Used to pre-press materials into log-shaped forms, cut them, and compress them again before ejecting the final bales. Logger balers are commonly applied in the forestry, scrap metal, and demolition industries for efficient material handling and transport.

Not sure which baler type matches your material? Use our baler selection guide or connect with a manufacturer for personalized advice.

Applications for Baler Machines: Where Are Balers Used?

Baler machines play a vital role in a wide range of industrial, commercial, municipal, and agricultural settings—wherever efficient waste reduction, recycling, or material consolidation is required. By compacting bulky recyclables or waste, balers help organizations reduce landfill contributions, streamline logistics, and improve environmental sustainability.

Common industries and sectors that benefit from baler machines include:

- Paper mill industries: Consolidate wastepaper, office paper, and cardboard for recycling or resale.

- Distribution centers and warehouses: Manage high volumes of packaging waste, including cardboard, shrink wrap, and pallets.

- Municipalities and public works: Facilitate transfer, sorting, and disposition of solid waste, recyclables, and refuse in city or county-run facilities.

- Metal processing and scrap yards: Compress ferrous and non-ferrous metals for efficient storage, transport, and recycling.

- Plastic producers and processors: Bale plastic bottles, films, packaging, and industrial byproducts for downstream recycling or disposal.

- Recycling centers: Compact paper, metal, cardboard, and plastics into uniform bales to maximize market value and minimize storage costs.

- Agricultural operations: Package hay, straw, or silage for feed, bedding, or biomass fuel.

- Food and beverage manufacturers: Utilize liquid extraction balers to efficiently dispose of packaging and reduce waste hauling fees.

- Textile and clothing recycling facilities: Compress used fabric, garments, and fibers for export or further processing.

Are you looking for industry-specific baler solutions? Contact our team to discuss your unique application and get matched with the right equipment.

Advantages Of Using Baling Machines: Key Benefits for Businesses

Investing in a baler machine delivers a host of operational, financial, and environmental benefits for organizations seeking to optimize their waste management and recycling practices. Here are some compelling advantages of baler machines:

- Significant reduction in recycling and waste disposal costs: Baled materials occupy less space, reducing haulage frequency and tipping fees.

- Enhanced storage and logistics efficiency: Uniform, stackable bales streamline warehouse management and enable the use of standard pallets and forklifts.

- Revenue generation from recyclables: Many recyclers pay a premium for baled materials, improving your facility's bottom line.

- Improved workplace safety and cleanliness: Containing waste in bales reduces clutter, minimizes trip hazards, and promotes compliance with health and safety regulations.

- Environmental sustainability: By diverting recyclable materials from landfills, organizations reduce their carbon footprint and support circular economy initiatives.

- Customizable solutions for varied materials: Modern balers are engineered to handle paper, cardboard, plastics, metals, textiles, agricultural byproducts, and more.

- Labor savings through automation: Automated feeding and tying systems reduce manual handling and increase productivity.

Considering adding a baler to your facility? Get advice on sizing, features, and ROI from our industry experts.

Disadvantages Of Using Baling Machines: What to Consider Before Purchasing

While baler machines offer substantial advantages, it’s important to recognize and plan for potential drawbacks when assessing your equipment investment:

- Routine maintenance requirements: Balers include hydraulic, electrical, and mechanical components that require regular inspection and servicing to prevent breakdowns and prolong equipment lifespan.

- Higher upfront and ownership costs for large-capacity models: Industrial balers can be expensive to purchase and install, with costs scaling based on size, automation, and material handling capabilities.

- Operational safety risks: Balers are powerful machines that can pose hazards if not operated by properly trained personnel. Comprehensive training, safety features, and ongoing supervision are essential.

- Space constraints: Large horizontal or two-ram balers require significant floor space and may necessitate facility modifications.

- Material contamination risks: Mixing incompatible materials in the same bale can reduce recyclability or market value; proper sorting procedures are necessary.

How can you mitigate the risks of baler ownership? Ask our team about maintenance plans, safety training, and facility planning support.

Choosing the Proper Baling Machine Manufacturer: A Buyer's Guide

Selecting the right baling machine manufacturer is crucial for maximizing performance, reliability, and return on investment. With many baler suppliers in the market, it’s essential to evaluate your options based on expertise, product range, after-sales support, and custom engineering capabilities.

Key factors to consider when choosing a baling machine manufacturer or supplier:

- Industry experience and specialization: Look for manufacturers with a proven track record in your sector—whether it’s recycling, agriculture, food processing, or manufacturing.

- Comprehensive product portfolio: Ensure the supplier offers the right type and size of baler for your material stream, facility layout, and throughput requirements.

- Customization and integration: Leading manufacturers can tailor balers with automation features, conveyors, or safety systems to fit your process.

- After-sales service and support: Reliable technical support, readily available spare parts, and preventative maintenance contracts are critical for minimizing downtime and protecting your investment.

- Certifications and compliance: Verify that balers meet relevant safety and environmental standards, such as CE, UL, or ISO certifications.

- Transparent pricing and financing options: Compare equipment pricing, warranty coverage, financing plans, and total cost of ownership—including installation, training, and ongoing maintenance.

To ensure the most productive outcome when purchasing a baling machine, we recommend comparing a minimum of four suppliers using our specialized Baling Machine Manufacturer Directory. Each manufacturer profile highlights areas of expertise, production capabilities, and key product offerings. Our easy-to-use contact forms allow you to communicate directly with suppliers for more information, technical advice, or to request a quote.

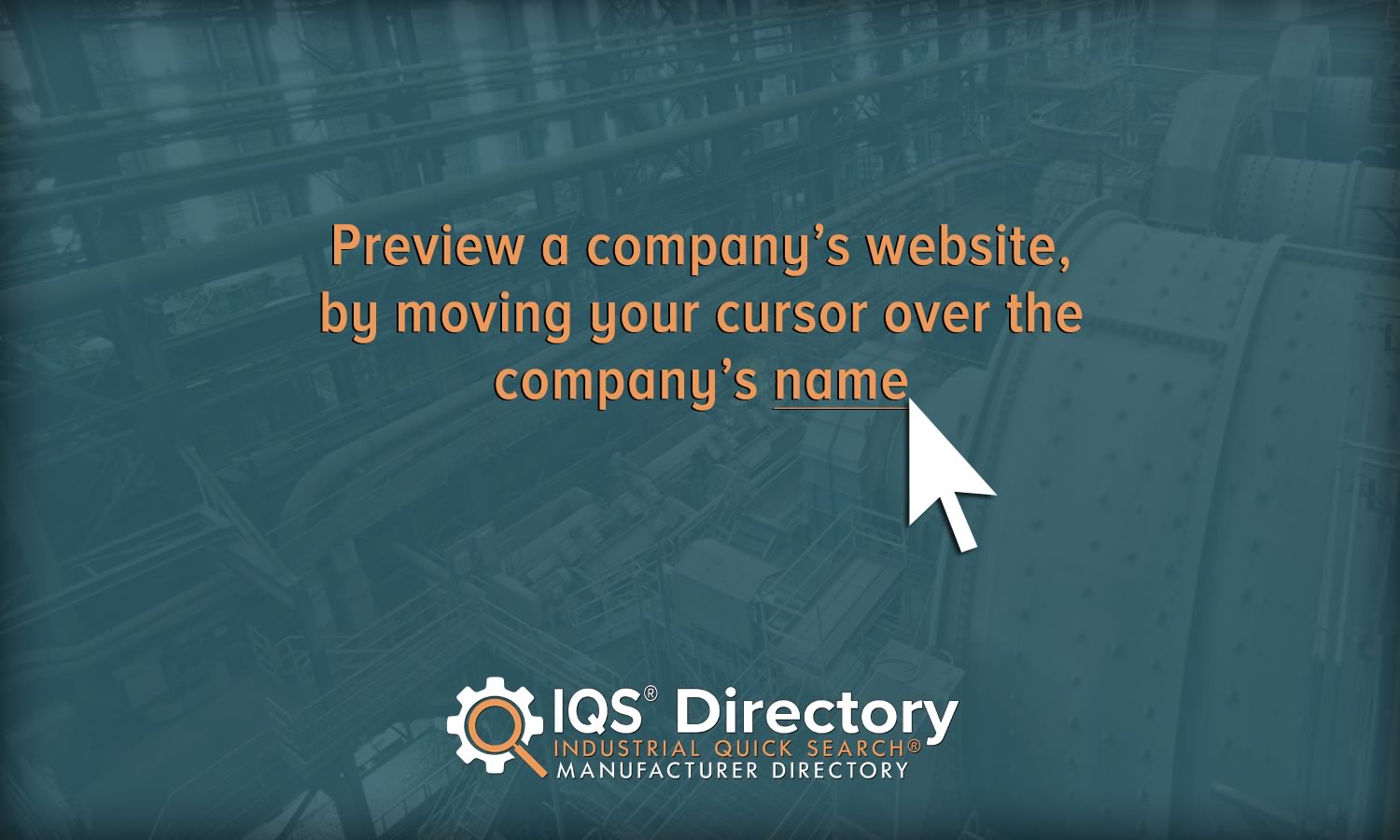

Additionally, use our proprietary website previewer to gain insight into each manufacturer's specialization, and take advantage of our streamlined RFQ (Request for Quote) process to contact multiple baling machine companies with a single message—saving you time and ensuring you get the best possible deal.

Ready to start your baler buying journey? Browse our directory now or reach out for a personalized consultation.

Frequently Asked Questions About Baler Machines

- What is the difference between vertical and horizontal balers?

Vertical balers are typically used for smaller volumes and require manual loading, making them best for retail stores and small businesses. Horizontal balers handle larger volumes, offer automated feeding and tying, and are suitable for industrial or high-throughput applications. - What materials can be processed in a baler machine?

Common materials include cardboard, paper, plastics (PET, HDPE, LDPE), metals (aluminum, steel), textiles, and agricultural products like hay and straw. Some balers are specialized for liquids or scrap metals. - How do I determine the right size baler for my operation?

Assess your average daily or weekly material volume, available floor space, material type, and manual vs. automated processing preferences. Consulting with a reputable manufacturer or distributor is recommended. - How much maintenance do balers require?

Regular maintenance—including hydraulic checks, lubrication, cleaning, and safety inspections—is necessary to ensure optimal performance and longevity. Many suppliers offer maintenance plans or support agreements. - Are financing or leasing options available for baler machines?

Yes, many manufacturers and distributors provide flexible financing, rental, or leasing programs to help businesses acquire baling equipment with manageable payments.

Still have questions about baler machines, recycling equipment, or waste management solutions? Contact our team for expert guidance and personalized recommendations.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services