A bailer, also spelled baler, greatly improves the convenience of managing and transporting garbage. balers can compress almost any material, from very hard to soft. Materials used in bailing include paper, cardboard, OCC, ONP, books, magazines, plastic bottles, plastic film, rigid plastic, foam, palm fiber, coir fiber, used clothing, wool, textile, cans, tins, and aluminum scraps. balers make carrying and storing this complexity of waste much easier. As a result, the market for trash recycling is flooded with these bailer machines. The most popular kind of balers are hydraulic power bailer units that can crush mechanically. Read More…

Since 1962, Maren has led the industry, building powerful and reliable manual tie, automatic tie and two ram balers, shredders and conveyors. That’s why many of the most successful paper & box plants, distribution centers, post consumer recyclers, and printers rely on Maren Balers to bolster their bottom line. Maren’s reputation for great customer service has carried from generation to...

In Business for over 100 years, Harris has maintained its position as the industry leader by paying attention to its customers needs. Our vertical, horizontal and 2-ram balers process recovered papers, paperboard, plastics, solid waste and light ferrous and non ferrous metals. Harris supplies the right equipment for your application.

The only thing stronger than an Excel baler is the loyalty of our customers. Excel continues to break new ground by designing equipment with energy-saving technologies, developing balers to fit your business and solve your problems, and introducing products that process more material and make you more money. While the competition makes their balers cheaper, we make Excel balers better!

SSI Shredding Systems provides a wide range of waste management products, including industrial shredders, industrial balers, industrial reducers and industrial compactors.

Founded in 1981, Ely Enterprises, Inc. has established itself as a leader in the baler manufacturing industry, specializing in premium baler products essential for effective material handling and waste management. Our balers are designed to maximize efficiency, reduce waste, and help companies optimize their recycling processes, benefiting industries from recycling and manufacturing to waste...

If you are currently paying for the disposal of cardboard, paper, plastic or non-ferrous metals; than consider International Baler Corporation & our range of balers and related equipment.

More Bailer Manufacturers

Principle of Operation of balers

The full-automatic waste paper baler's lead frame is made up of four sets of lead devices that are mounted on a frame. The wheels on the bottom of the compaction frame, which is a welded component, can move horizontally along the main slide rail when a hydraulic cylinder is pushed. Two horizontal beams are mostly used to fasten the lifting platform. The lifting platform can be raised vertically by pumping two hydraulic cylinders. The waste-paper baler has undergone continual innovation and reform as proper waste disposal has gained importance, which has been crucial for environmental protection.

Types of balers

There are two basic construction types for balers, vertical and horizontal, which refer to the direction in which material passes through the machine, depending on the intended purpose. Top-loading vertical balers are frequently utilized for waste goods and lightweight materials. Vertical balers are single-load devices that require manual unloading, although they are more cost-effective and smaller than horizontal balers.

Horizontal balers

A horizontal waste baler is a commercial recycling device that compresses rubbish into dense bales the size of mills. A horizontal baler is economically viable when the business generates at least 4,400 pounds (2,000 kg) of cardboard or plastic waste daily.

Large quantities of recyclable garbage (such as cardboard or plastic) can be compressed into a much more manageable shape with a horizontal baler for simpler storage and transportation. A closed-end and an open-end baler are the two varieties of horizontal balers. The open-end baler is designed for high production, while the closed-end baler is intended for reduced bale production. The open-end baler also comes in a more potent two ram version than a single ram.

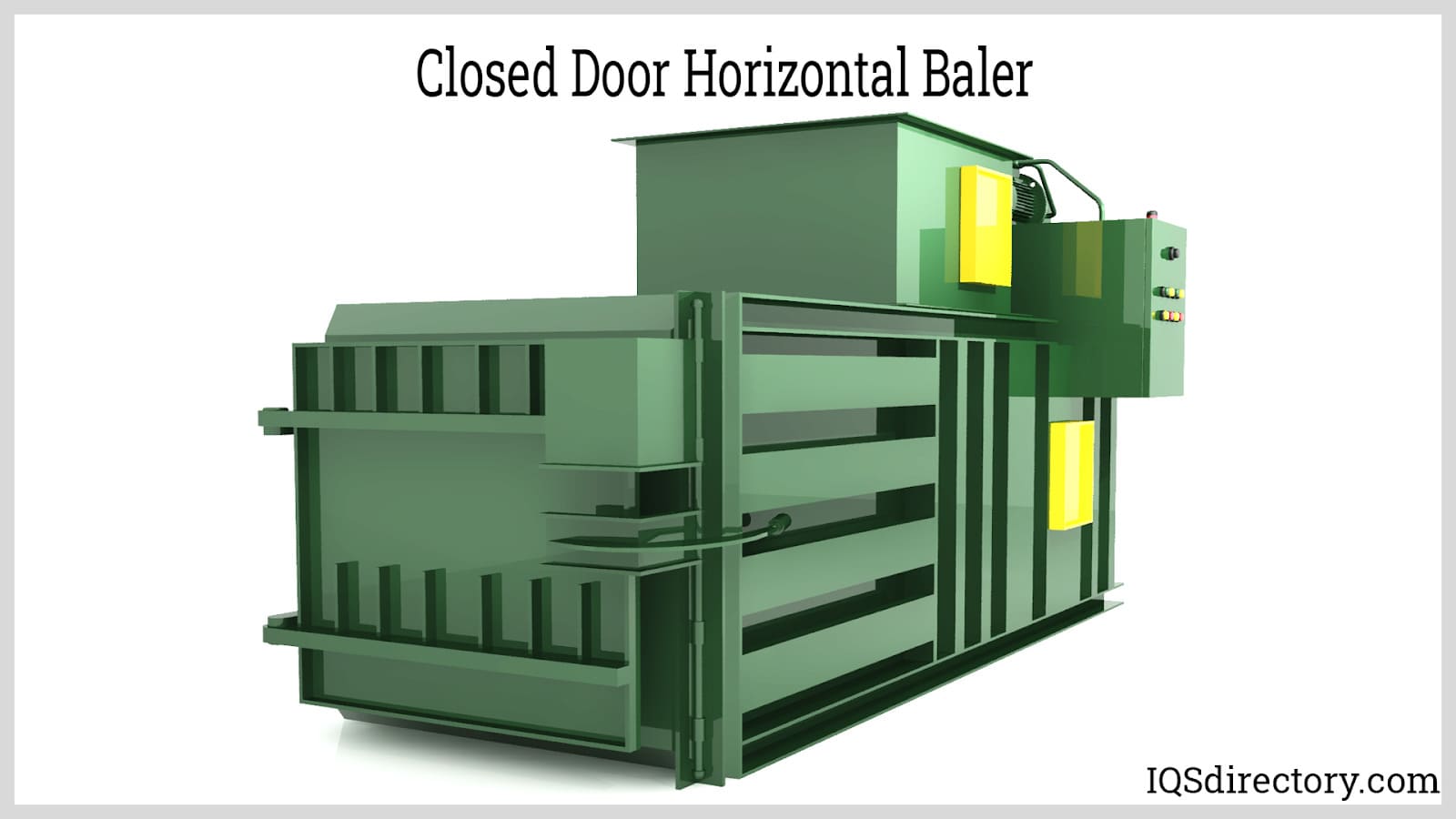

Closed-End Horizontal balers

A closed-end horizontal baler is an "entry-level" recycling baler. This type of baler is identified by the sealed pressing chamber. It’s smaller than an open-end auto-tie baler. A single ram compresses the trash horizontally as it pushes it against a closed door within a baling chamber. Consequently, the device is also called a "closed-door baler." An operator is not required during the baling process because compressing garbage is automatic.

A conveyor can be utilized as an optional means of supplying cardboard or plastic garbage to the hopper. However, other options include using a bin lifter, a forklift with a self-dumping hopper, or manually feeding it.

Open-end Horizontal balers

An open-end horizontal baler is a "high-end" recycling baler. The auto-tie feature of the bales and the open rear end of the extrusion chamber define this automatic horizontal baler machine. The open-end baler is a powerful extrusion baler that can compress large amounts of bulky wastes like corrugated cardboard. The baler's base model has a single, energy-efficient ram.

A more potent two-ram extrusion baler can compress more waste streams than a single-ram extrusion baler and is ideal for bigger volumes of bulkier garbage. The upper cylinder exerts continual stress on the extrusion chamber's end segment. This cylinder applies constant pressure to the sides of the chamber to produce tight, thick bales. The cylinder can also loosen up in between the baling process for a smoother output.

Vertical balers

Plastic bottles, paper, cardboard packaging, light gauge ferrous and non-ferrous metals, and plastic packaging are all forms of industrial waste. Everything can be bundled into a bale. Balers can range from small single-phase devices that can produce a bale that weighs 88 lbs (40 kg) to huge balers that can produce bales that weigh over 1 ton and are ideal for commercial use.

Application of balers

Many different companies and organizations use industrial balers, including:

- Manufacturing establishments

- Office buildings

- Restaurants and hotels

- Supermarkets

- Warehouses

- Recycling facilities

- Schools and colleges

- Retail establishments

- Shopping malls

Pros of balers

- Saves space

- High compacting efficiency

- Increased recycling rates

- Generates income

- Decreases labor costs

- Reduces fire risks

Cons

- Extensive investment

- Tools required

- Routine maintenance

- Investment recommended

- Education of employees recommended

- Cost of cardboard trash varies

- Vertical (interior) space must be conserved wisely

- Not a computerized procedure

- Not every bale meets the "mill standard"

- Noise production solely for cardboard

- Typically need a 3-phase electrical source

Choosing the Proper Bailers Manufacturer

To make sure you have the most constructive outcome when purchasing Bailers from a Bailers Supplier, it is important to compare at least 6 Manufacturers using our list of Bailers manufacturers. Each Bailers Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Bailers company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Bailers businesses with the same quote.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

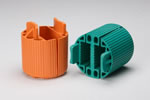

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services