Waste Balers

Waste balers are used not only for the compression and easy disposal of waste, but also to help create a secure bundle in which to transport waste to a repurposing or recycling facility. Read More…

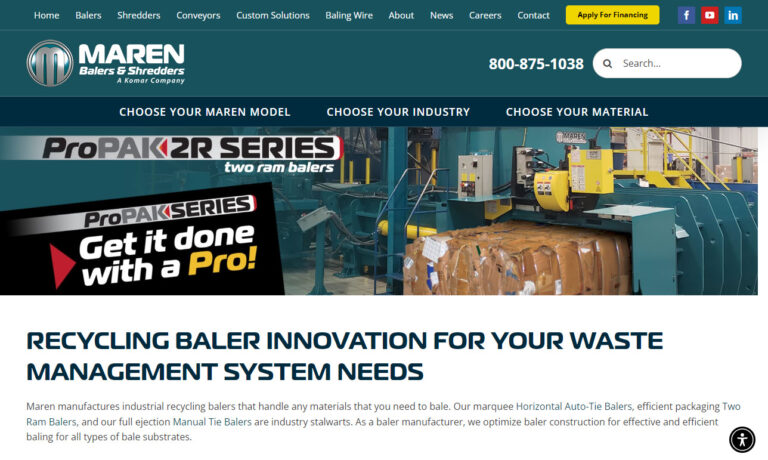

Since 1962, Maren has led the industry, building powerful and reliable manual tie, automatic tie and two ram balers, shredders and conveyors. That’s why many of the most successful paper & box plants, distribution centers, post consumer recyclers, and printers rely on Maren Balers to bolster their bottom line. Maren’s reputation for great customer service has carried from generation to...

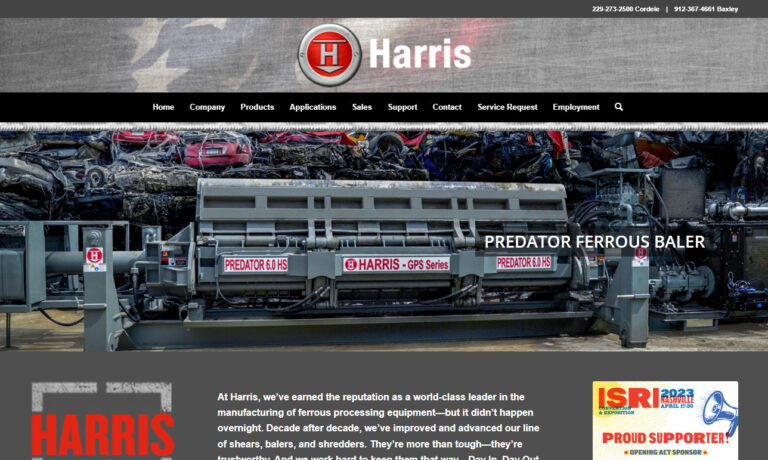

In Business for over 100 years, Harris has maintained its position as the industry leader by paying attention to its customers needs. Our vertical, horizontal and 2-ram balers process recovered papers, paperboard, plastics, solid waste and light ferrous and non ferrous metals. Harris supplies the right equipment for your application.

The only thing stronger than an Excel baler is the loyalty of our customers. Excel continues to break new ground by designing equipment with energy-saving technologies, developing balers to fit your business and solve your problems, and introducing products that process more material and make you more money. While the competition makes their balers cheaper, we make Excel balers better!

SSI Shredding Systems provides a wide range of waste management products, including industrial shredders, industrial balers, industrial reducers and industrial compactors.

Founded in 1981, Ely Enterprises, Inc. has established itself as a leader in the baler manufacturing industry, specializing in premium baler products essential for effective material handling and waste management. Our balers are designed to maximize efficiency, reduce waste, and help companies optimize their recycling processes, benefiting industries from recycling and manufacturing to waste...

If you are currently paying for the disposal of cardboard, paper, plastic or non-ferrous metals; than consider International Baler Corporation & our range of balers and related equipment.

More Waste Baler Manufacturers

A waste baler may be designed to fit the needs of its user, varying based on size and type of materials they wish to compress and transport. The basic design of a waste baler, however, consists of three main parts: the container, the compactor and the power unit. First, waste is collected in the container. Once it is full, the waste is compacted into a bundle or bale by the compactor.

Commonly, this compaction is followed by a wrapping process. Wrapping waste bales helps further protect them for future use. It does so by protecting the bundle from water damage and by making sure it is contained, lessening the likelihood of issues like wind-blown litter, odors, vermin or damage caused by dislodged waste.

Waste balers are an advantageous purchase or rental for a number of reasons. Waste balers often make it possible to collect even the smallest pieces or shards for baling, like unsellable pieces of textile cloth or shards of scrap metal. Additionally, they are an economical choice for waste collection and transport, whether that is for the purpose of disposal, recycling or selling to another company for repurposing.

An indirect benefit of waste balers is the revenue created by this efficient collection and redistribution system. Depending on the size of your business and the extent of your compacting needs, you may consider purchasing a waste baler with which to economically dispose of and redistribute your leftover material and waste.

When considering a waste baler, ask yourself the following questions: "What do I plan to bale?" "What is the largest size of the majority of the material?" "How much material will be baled at the busiest hour?" "How will the baler be fed?" "How will the bales be stored?" "What is the shipping method?" "Is there a maximum weight on the shipping conveyance?" and "Will the bales be tied manually or automatically?" Keeping these questions in mind, you will be on your way to making a fantastic investment.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services