Horizontal balers are machines used to compress waste materials into compact, easy-to-manage bales. They are commonly used in recycling and waste management operations to reduce waste volume and improve handling efficiency. Read More…

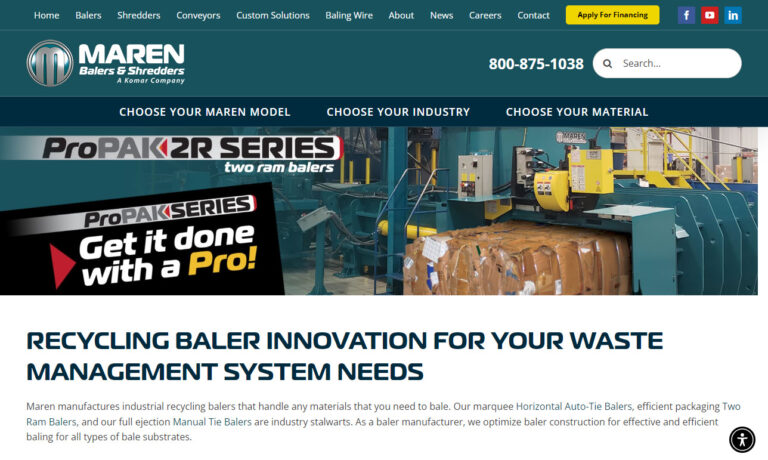

Since 1962, Maren has led the industry, building powerful and reliable manual tie, automatic tie and two ram balers, shredders and conveyors. That’s why many of the most successful paper & box plants, distribution centers, post consumer recyclers, and printers rely on Maren Balers to bolster their bottom line. Maren’s reputation for great customer service has carried from generation to...

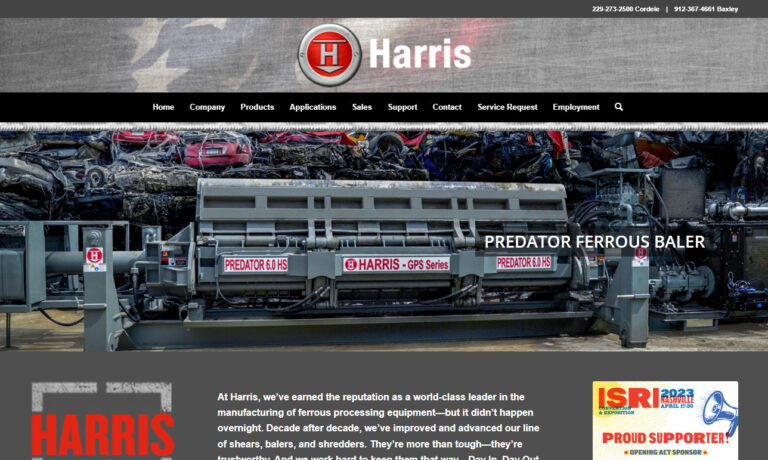

In Business for over 100 years, Harris has maintained its position as the industry leader by paying attention to its customers needs. Our vertical, horizontal and 2-ram balers process recovered papers, paperboard, plastics, solid waste and light ferrous and non ferrous metals. Harris supplies the right equipment for your application.

The only thing stronger than an Excel baler is the loyalty of our customers. Excel continues to break new ground by designing equipment with energy-saving technologies, developing balers to fit your business and solve your problems, and introducing products that process more material and make you more money. While the competition makes their balers cheaper, we make Excel balers better!

SSI Shredding Systems provides a wide range of waste management products, including industrial shredders, industrial balers, industrial reducers and industrial compactors.

Founded in 1981, Ely Enterprises, Inc. has established itself as a leader in the baler manufacturing industry, specializing in premium baler products essential for effective material handling and waste management. Our balers are designed to maximize efficiency, reduce waste, and help companies optimize their recycling processes, benefiting industries from recycling and manufacturing to waste...

If you are currently paying for the disposal of cardboard, paper, plastic or non-ferrous metals; than consider International Baler Corporation & our range of balers and related equipment.

More Horizontal Baler Manufacturers

Components of Horizontal Balers

Horizontal balers consist of several key components that are essential to their operation. These components include the hopper, ram, bale chamber, tying mechanism, and control system. Each component serves a unique purpose and works together to create a functioning horizontal baler.

The hopper is where the waste material is loaded into the machine. The ram is responsible for pushing the waste material into the bale chamber, where it is compressed into a bale. The tying mechanism secures the bale with twine or wire, while the control system regulates the machine's operation.

Variations Among Horizontal Balers

Horizontal balers come in various designs and configurations, each tailored to meet specific needs. Some common variations of horizontal balers include single-ram vs. dual-ram, open-end vs. closed-end, and manual-tie vs. auto-tie.

Single-Ram Horizontal Balers

Single-ram horizontal balers have a single compression chamber and are ideal for processing large volumes of similar materials, such as cardboard or plastic.

Dual-Ram Horizontal Balers

Dual-ram horizontal balers, on the other hand, have two compression chambers and are better suited for handling a variety of materials.

Open-End Horizontal Balers

Open-end horizontal balers have an opening on one side, allowing for continuous feeding of waste material.

Closed-End Horizontal Balers

Closed-end horizontal balers, on the other hand, have a fully enclosed chamber and are better suited for processing materials that require a higher degree of compression.

Manual-Tie Horizontal Balers

Manual-tie horizontal balers require manual tying of bales using twine or wire, while auto-tie horizontal balers have an automatic tying mechanism that secures the bales.

It is important to note that a horizontal baler can be classified in multiple ways since a horizontal baler can have features that fall into more than one of these categories. For example, a horizontal baler can be both a single-ram and a closed-end baler. Similarly, it's possible to have a manual-tie, closed-end baler. Manufacturers design and produce horizontal balers with different features and capabilities to meet the specific needs of different industries and waste materials.

Considerations Regarding Horizontal Balers

While horizontal balers offer many benefits, there are also some considerations to keep in mind. These include maintenance requirements, operational costs, and safety concerns. Maintenance requirements can be extensive, and the machine may require regular cleaning and repairs. Operational costs, such as energy consumption and labor costs, can also be significant. Additionally, horizontal balers can pose safety risks, as they involve heavy machinery and require proper training and safety procedures to operate safely.

Benefits of Horizontal Balers

Despite these considerations, horizontal balers offer many benefits. They are an efficient way to manage waste, as they reduce the volume of waste material and minimize the need for frequent pickups. They also save space, as the bales can be stacked and stored in a compact manner.

Additionally, horizontal balers are cost-effective, as they reduce waste-handling costs and can generate revenue by selling the bales to recycling facilities. They also promote sustainability by reducing the amount of waste sent to landfills and promoting recycling efforts.

Applications of Horizontal Balers

Horizontal balers have many applications in various industries, such as:

Recycling Facilities

In recycling facilities, horizontal balers are used to compress materials such as cardboard, plastic, and metal into compact bales that can be transported more efficiently.

Manufacturing Plants

Manufacturing plants use horizontal balers to compress materials such as foam, textiles, and paper into bales for storage and transport.

Distribution Centers

Distribution centers use horizontal balers to compress packing materials such as cardboard and plastic to reduce waste and improve handling efficiency.

Waste Management Facilities

Waste management facilities use horizontal balers to manage waste materials and reduce the volume of waste sent to landfills.

Agricultural Operations

Agricultural operations use horizontal balers to compress materials such as hay and straw for storage and transport.

Retailers

Retailers use horizontal balers to compress cardboard and plastic packaging materials generated by their operations.

Hospitals

Hospitals use horizontal balers to compress medical waste such as gowns, gloves, and other disposable materials generated by their operations.

Municipalities

Municipalities use horizontal balers to manage waste generated by their communities. This includes compressing materials such as paper, cardboard, and plastic to reduce waste volume and transport costs.

Data Centers

Data centers generate large quantities of cardboard, foam, and plastic packaging materials that can be compressed into bales using horizontal balers.

Logistics

Logistics companies use horizontal balers to compress materials such as plastic wrapping, pallets, and strapping to reduce waste volume and transport costs.

Landscaping

Landscaping companies use horizontal balers to compress materials such as tree branches, leaves, and grass clippings into bales for storage and transport.

Printing Companies

Printing companies use horizontal balers to compress paper waste generated by their operations.

Choosing the Correct Horizontal Baler Manufacturer

To ensure you have the most beneficial outcome when purchasing a horizontal baler from a horizontal baler manufacturer, it is important to compare several companies using our directory of horizontal baler manufacturers. Each horizontal baler manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each horizontal baler business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple horizontal baler companies with the same form.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services